FluXion® Ester Technology

Unleash Peak Performance

FluXion® Ester Technology

FluXion® Ester Technology is not just another engine oil; it's a testament to XHYPE’s commitment to push boundaries of automotive innovation. With a legacy of excellence and a passion for performance, we present a game-changing solution that redefines what you can expect from engine lubrication.

Precision blended to win

Typical results

Results speak for themselves

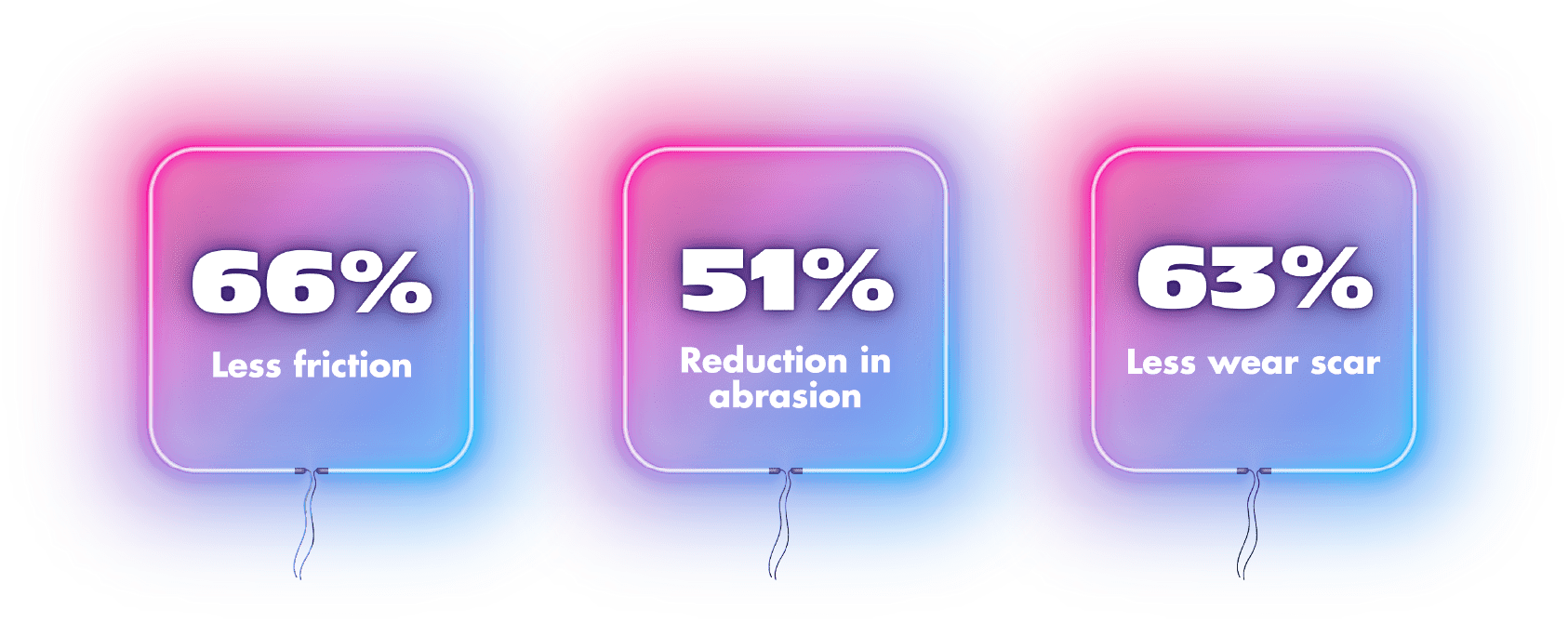

Coefficient of Friction Test

FluXion® oil showed 66% less friction

Coefficient of Friction test conditions

- Equipment used: Ducom 4-Ball Tester FBT-3

- ATSM Method: ASTM D 5185

- Load: 392N

- Duration: 60 min

- Temperature: 120º c

- Speed: 600 rpm

Wear Scar Coefficient of Friction Test

FluXion® oil showed 63% less wear scar

During testing, a typical 5W-40 oil produced a 0.559mm scar, whereas 5W-40 oil with advanced Fluxion® Ester Technology demonstrated a much smaller 0.342mm scar.

This decreased Scar Ratio implies FluXion® was more effective in minimising wear and abrasion, indicating better protection for engine components.

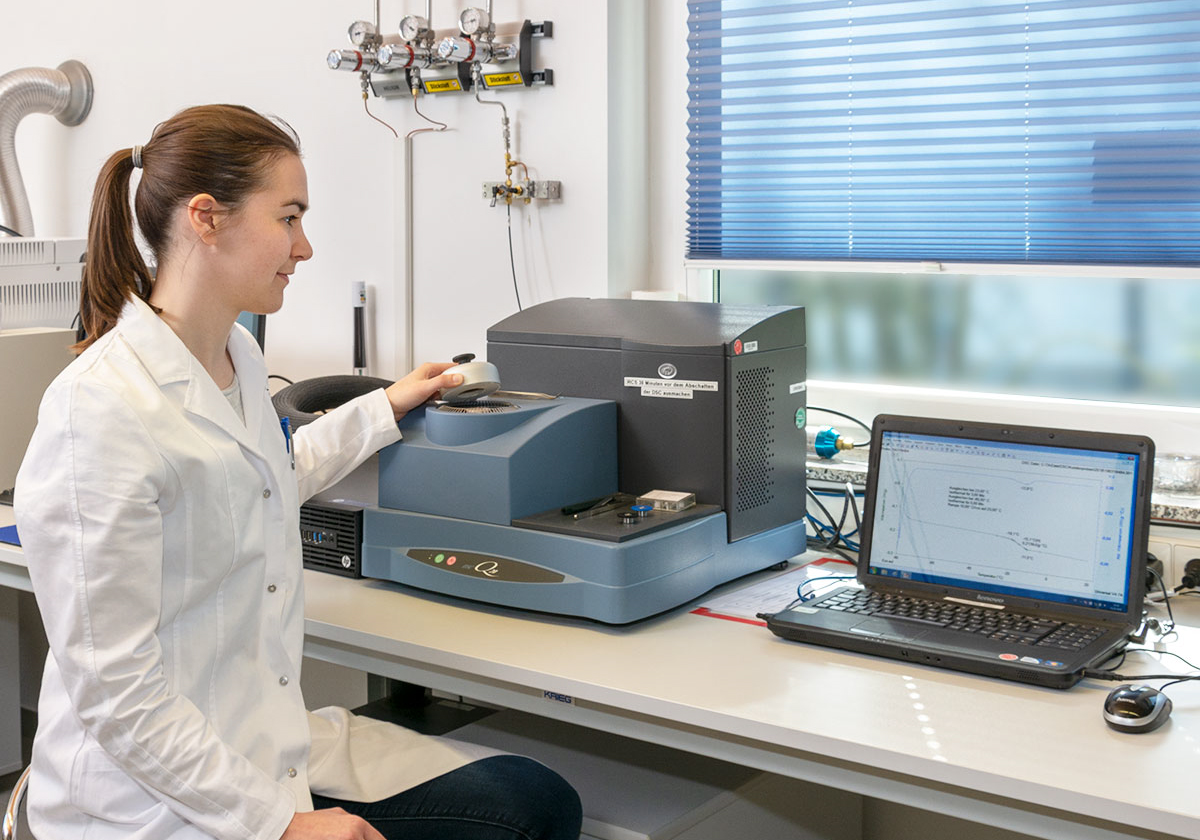

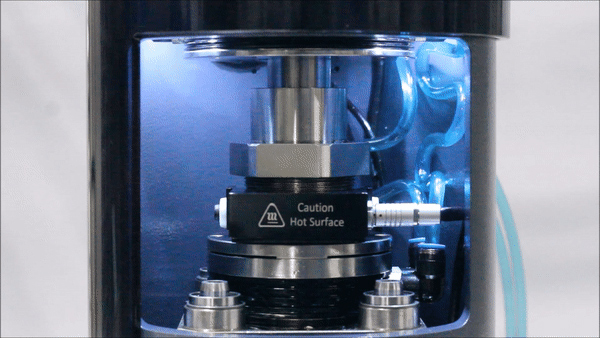

Pressure Differential Scanning Calorimetry (PDSC) Test

Oxidative stability is a crucial property for lubricating oils, as oxidation can lead to the formation of acids, sludge and varnish, which in turn can cause corrosion, increased viscosity and the deterioration of the oil’s lubricating properties.

FluXion® oil showed a 36% Higher oxidation onset time

During testing, a typical 5W-40 oil endured for just 24 minutes, whereas 5W-40 oil with advanced Fluxion® Ester Technology demonstrated impressive resilience, lasting 37.5 minutes showing improved oxidative stability.

PDSC test conditions

- Equipment: PerkinElmer Pyris 1 DSC Differential Scanning Calorimeter

- Sample weight: 3.100mg

- Heat: from 30ºc to 200ºc @100ºc/Min

- Hold: 60min at 200ºc